MEETING THE MOST DEMANDING REQUIREMENTS.

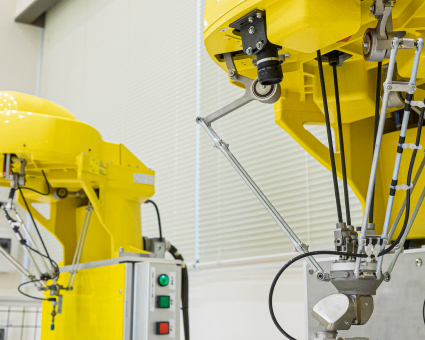

INDUSTRIAL ROBOTIC SOLUTIONS TO PRODUCTION LINE PROBLEMS.

INDUSTRIAL ROBOTS

Feature

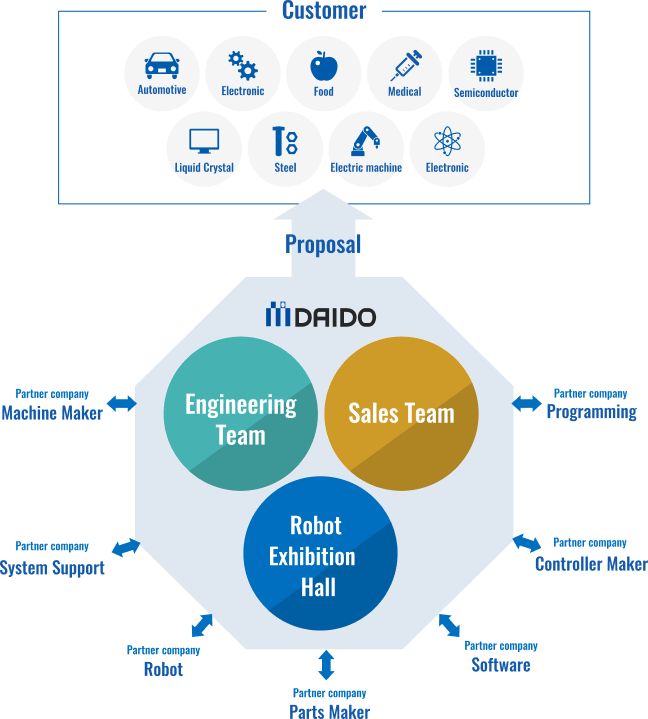

Daido is a nationwide company well versed in the technology industry with experts that can suggest possible solutions to your manufacturing problems.

Daido's Advantage

Using our industry wide experience we offer solutions tailored specifically to our customer’s needs.

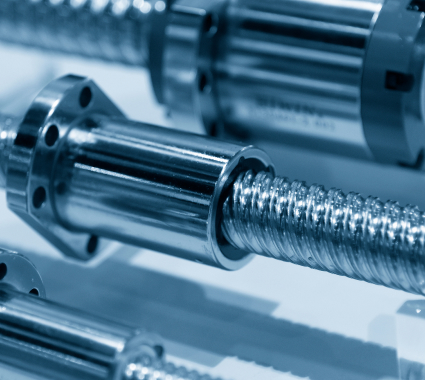

Together with engineers from cooperating manufacturers, we use our accumulated experience and achievements to propose not a production line of a fixed form, but an original production line tailored to the processes at the customer's plant. we perform structural design using 3D, etc., and adjust precision mechanical parts.

We utilize our strength as a general trading company to manufacture, wire, assemble, and adjust mechanical parts in cooperation with our customers' engineers.

Service Flow

Initial Consultation

・We review the specifications to understand the intended use, work dimensions, shapes, quality, precision, and speed requirements

・We can provide proposals for new projects based on our extensive experience.

・For interested clients, we can also handle the creation of the specifications document.

-

Proposal

We conduct thorough preliminary research to select the most suitable manufacturers.

-

Quotation Submission

We provide quotations either from our in-house designers or from our partner manufacturers.

-

Order Placement

Upon receiving your order, we commence detailed design work.

-

Schedule Presentation

We confirm the delivery date and communicate the schedule to you.

-

Design Review (DR)

-

Approval

After the DR, we proceed with detailed drawings based on the confirmed content.

-

Ordering of Manufacturing and Commercial Parts

We leverage our extensive supplier network for procurement and can also recommend processing manufacturers.

-

Parts Assembly

Our production management team oversees the process with a detailed schedule.

-

Assembly Start

Veteran technicians from our systems division supervise the assembly process.

-

On-Site Inspection and Delivery Management

We create progress schedules and conduct on-site inspections to verify specifications together.

-

Installation

・Our qualified personnel manage the on-site installation.

・Our engineers and partner manufacturers assist with on-site setup.

・We provide technical support for robot teaching, image adjustment, tracking, and other setup adjustments during installation.

-

Support

Comprehensive after-sales support to ensure continued satisfaction and optimal performance.

Products

the DKS Group has a strong relationship with a multitude of manufacturers. Alongside our various divisions, including our robotics team, we work together with the customer to expand the possibilities of mechatronics. We combine our unique experiences to help develop, design, and produce anything the customer may need.

Contact Us

DAIDO - PROVIDING INNOVATIVE INDUSTRIAL ROBOT SYSTEMS ACROSS ALL MANUFACTURING INDUSTRIES.

POTTERY WHEELS THAT MOTIVATE TO CREATE

CONTACT A SALES ASSOCIATE TODAY!